Custom Forging Truck Parts High Precision CNC Machining Turning Milling Polished Coating Clear Anodized Titanium Alloy Part Service

Professional Forging Parts Manufacturer in China Molding R&D, Forging, Machining, Surface Treatment, Inspection, Packing

Send your inquiryDESCRIPTION

Basic Info.

| Surface Treatment | Sand Blasting |

| Forging Tolerance | +/-0.1mm |

| Standard | AISI,BS,JIS,GB... |

| Certification | RoHS, ISO 9001:2000, ISO 9001:2008 |

| OEM | Acceptable |

| Drawing | Pdf/3D/Dwg |

| Quality Control | 100% Inspection Before Shipment |

| Capacity | 10000tons/Year |

| Transport Package | Carton/Pallet |

| Specification | 0.1kg~1000kg |

| Trademark | XHX |

| Origin | Qingdao |

| HS Code | 7325101000 |

| Production Capacity | 10000tons/Year |

Product Description

Professional Forging Parts Manufacturer in China

Molding R&D, Forging, Machining, Surface Treatment, Inspection, Packing & Loading, Aftersale service etc.

| Main Process | Material Cutting, Material Heating, Forging, Heat Treatment, Blasting&Polishing, CNC Machining |

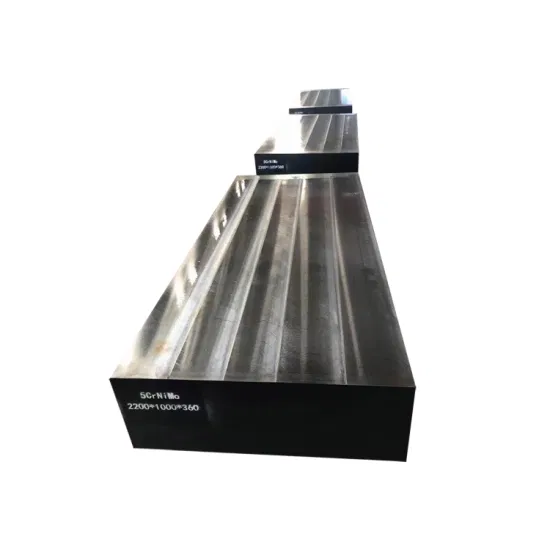

| Material | Aluminum, Carbon Steel, Stainless Steel Brass, ,DC53 or as customer request |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Primer Painting , Powder Coating, ED- Coating, Chromate Plating, Zinc Plating, Dacromat Coating, Finish Painting |

| Application | 1. Construction: lifting anchors for precast concrete, spherical head anchors |

| 2. Automotive industry: piston, connecting rods, cams, camshafts, crankshafts | |

| 3. Heavy machinery: Rock breaker, excavator parts | |

| 4. Energy: Anvil, gate valve, wellhead control EQP, wellhead EQP | |

| 5. Defense: Black receiver, aluminum trigger guards and receivers | |

| 6. Truck: Cylinder heads, oil sump, clutch housing, front and rear brake calipers. | |

| Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/ Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Testing Machine | CMM, Digital Height Gauge, Caliper, Coordinate Measuring Machine, Projecter Machine, Roughness Tester, Hardness Tester and so on |

| Certificate | ISO9001, CE, TUV, SGS or as your requirement to do test by the third party |

| Delivery time | 10-15 days for sample, |

| 35-40 days for bulk order | |

| Packing | Plywood pallet, plywood box or as per your requirement |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Service | Warm and quick response service provided by the professional |

| Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

Related Products

-

![Hon Ye Custom 321/316 L / 317 L / 309 S / 310 S / 347 Mirror 2 B Polishing Titanium/Aluminum/Zinc/Price of Steel Round Bar]()

Hon Ye Custom 321/316 L / 317 L / 309 S / 310 S / 347 Mirror 2 B Polishing Titanium/Aluminum/Zinc/Price of Steel Round Bar

-

![Titanium Bars ASTM Grade Gr1 Gr2 Density 4.51 and Very Popular]()

Titanium Bars ASTM Grade Gr1 Gr2 Density 4.51 and Very Popular

-

![Distal Dorsal Plate of Radius Titanium Fracture Full Types Implant Orthopedic Instruments Plate]()

Distal Dorsal Plate of Radius Titanium Fracture Full Types Implant Orthopedic Instruments Plate

-

![2022 Hot Sale Gr2 Gr5 G20cr2ni4 Forging Titanium Alloy Square Blocks]()

2022 Hot Sale Gr2 Gr5 G20cr2ni4 Forging Titanium Alloy Square Blocks